The other day my Schacht Flatiron spinning wheel arrived. "Ding-dong", said the Fed Ex man. I opened the door and squealed like a 5 year-old on Christmas morning. Mr. Fed Ex was startled; I grabbed the box and ran.

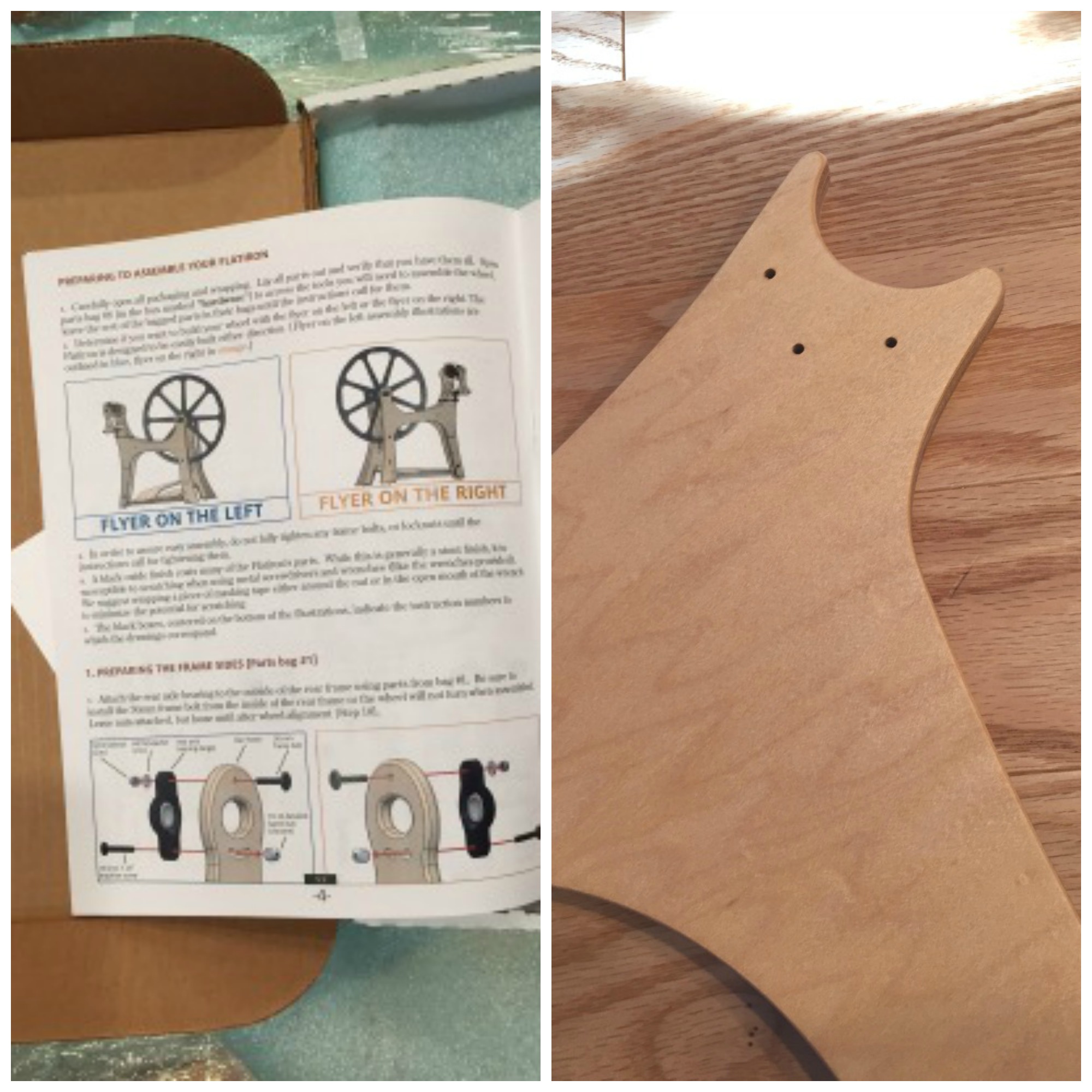

The Flatiron is a flat-packed wheel, completely flat in pieces, which makes me call it the Schacht-Ikea wheel and giggle like an idiot. When the wheel gets to you it is completely unassembled, you have to build it before you can spin.

I do not build things beyond Ikea furniture or an excellent cheese and nibbles pairing. I certainly don't build precision tools to spin on. But this box of parts was standing between me and my next spinning wheel. I was in. It took me four hours. It took Beth Smith, who builds wheels regularly, 90 minutes. I had issues with barrel nuts, bending wood, fiddly bits and there was also a fair amount of cussing. None of this was because of the wheel, it was because of my own stubborn.

There are a lot of pieces to this wheel, one of them looks like a cat, meow.

Right off the bat, I noticed a couple of things that are genius when you send people parts to build a precision tool. The instruction booklet comes divided in half AND color coded for either a right or left side orifice - you get to pick, depending on how you spin. The other is, each section of the build is numbered in the booklet and the nut and bolt-type parts needed for that section are in a correspondingly numbered sealed bag. I didn't get lost once.

I did have to bend wood, which gave me pause. The pieces of wood are flat, the wheel has parts that are curved. You have to screw parts together to make the wood curve. It gave me the wrong kind of hot flash. But I did it.

After displaying my wood -bending-while-menopausal prowess, I put my mostly assembled wheel up on a table. It was time to assemble the maiden, attach the treadles and true the wheel. If you have ever changed a bobbin on a Schacht, the maiden assembly will feel familiar. The treadle assembly on the other hand felt as familiar as juggling with my feet. But I got it done in one pass. There is a cool trick using spacers for aligning the wheel that takes five minutes. Very cool.

I can't stress how good the directions are, I never got lost. Also barrel nuts are simultaneously genius and hellish.

So give or take four hours, which included breaks and lunch, I had a new wheel that I built myself. It was very satisfying to build this wheel, plus if she ever has any problems or weird squeaks I'll have an excellent idea of where to look to fix it.

What did I spin on her first? I spun a little Louet oatmeal BFL. Then I took her to her first playdate.

Conveniently, my neighbor Alice was hosting spinning that day. So I took my wheel to a room full of spinners to share the new wheel love.

Everyone spun on it.

In a room of four spinners, one had a Flatiron on order and hadn't received it yet and one ordered one after she went home.

I'll spin for a few weeks on the wheel then let you know how she spins.

Of course, days after I built my wheel, Schacht posted a video on how to assemble a Flatiron.